Stay Ahead of Damage: Essential Upkeep Tips for Undercarriage Parts

Stay Ahead of Damage: Essential Upkeep Tips for Undercarriage Parts

Blog Article

Vital Guide to Undercarriage Components for Heavy Tools

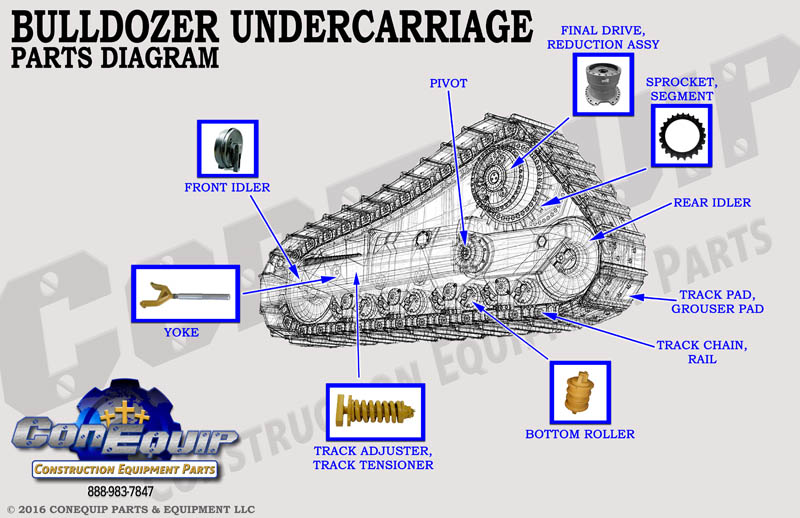

When it comes to heavy tools, the undercarriage plays a critical role in making sure efficient and smooth operations. Comprehending the complex information of undercarriage parts is crucial for making best use of the lifespan and performance of your machinery. From track chains to rollers and idlers, each part adds to the overall capability of the tools. Looking into the specifics of gears and various other undercarriage elements supplies very useful insights right into upkeep methods that can significantly influence the longevity of your hefty machinery. By comprehending the significance of these components and their upkeep demands, drivers can optimize the efficiency and durability of their devices, ultimately bring about cost financial savings and boosted operational performance.

Relevance of Undercarriage Parts

Recognizing the essential function that undercarriage components play in the efficiency and durability of heavy equipment is vital for effective upkeep and procedure - undercarriage parts. The undercarriage elements develop the structure on which the whole maker runs, sustaining the weight of the devices, giving security, and soaking up shock tons throughout procedure. A well-kept undercarriage not just ensures smooth operation but also contributes considerably to reducing downtime and repair work prices

The undercarriage consists of numerous necessary parts such as track chains, track footwear, sprockets, idlers, rollers, and track structures. The track chains and track shoes aid in giving traction and assistance, while the idlers and sprockets assist in driving the tracks smoothly.

Sorts Of Track Chains

Track chains are essential parts of hefty devices undercarriages, supplying the needed traction and support for effective operation. There are primarily 2 kinds of track chains utilized in hefty devices: secured and lubed track chains (SALT) and completely dry track chains. Sealed and oiled track chains are typically located in modern hefty machinery. These chains are pre-lubricated and secured to avoid dust, particles, and moisture from getting in the chain joints, ensuring smooth operation and expanding the chain's lifespan. On the other hand, completely dry track chains require normal manual lubrication to preserve optimal performance and stop early wear.

Duty of Rollers and Idlers

Rollers and idlers play a critical function in sustaining and assisting the track chains of heavy tools undercarriages, click reference adding to the total stability and efficiency of the equipment. Rollers are developed to support the weight of the devices and offer a smooth surface for the track chain to relocate along. They help disperse the weight uniformly, decreasing too much endure the track chain and making sure appropriate grip. Idlers, on the various other hand, guide the track chain and help maintain appropriate tension throughout the undercarriage system. By guiding the track chain in a regulated way, idlers prevent too much side-to-side motion, decreasing the risk of derailment and irregular wear.

Together, idlers and rollers operate in consistency to guarantee that the track chain stays in area, even on harsh surface, boosting the tools's efficiency and durability. Proper upkeep and regular inspection of idlers and rollers are essential to prevent early wear and potential malfunctions, ultimately maximizing the effectiveness and lifespan of hefty equipment undercarriages.

Recognizing Gears

One crucial facet of sprockets is ensuring correct positioning and tension to avoid early wear and damages. Misaligned gears can trigger uneven wear on the track chain, causing lowered effectiveness and prospective safety check out this site threats. Normal maintenance and inspection of sprockets are vital to determine any kind of signs of wear or imbalance promptly.

In addition, sprockets are available in various sizes and tooth arrangements, depending on the certain hefty devices and its desired use. Appropriate selection of sprockets based on the tools's specifications is essential to guarantee optimum performance and long life of the undercarriage system. Understanding the duty of sprockets and their upkeep demands is essential for maximizing the performance and life-span of heavy equipment undercarriages.

Maintenance Tips for Durability

To make certain the extended sturdiness and optimal performance of heavy devices undercarriages, persistent maintenance methods are necessary. Consistently checking undercarriage parts such as track footwear, rollers, idlers, and sprockets for wear and tear is essential. Correct track tension change is likewise important for try this lowering early wear on undercarriage parts.

Verdict

In final thought, undercarriage components are essential parts for heavy equipment, playing vital roles in maintaining stability and performance. Proper care and attention to undercarriage components are vital to maximizing equipment life expectancy and performance.

The undercarriage consists of different essential components such as track chains, track footwear, sprockets, idlers, rollers, and track frameworks. The track chains and track footwear help in providing grip and assistance, while the gears and idlers help in driving the tracks smoothly (undercarriage parts). There are largely 2 types of track chains made use of in heavy equipment: sealed and lubed track chains (SALT) and completely dry track chains. Appropriate choice and maintenance of track chains are crucial to ensure the total efficiency and long life of heavy tools undercarriages

Gears are indispensable components of heavy equipment undercarriages, responsible for moving power from the equipment to the track chain.

Report this page